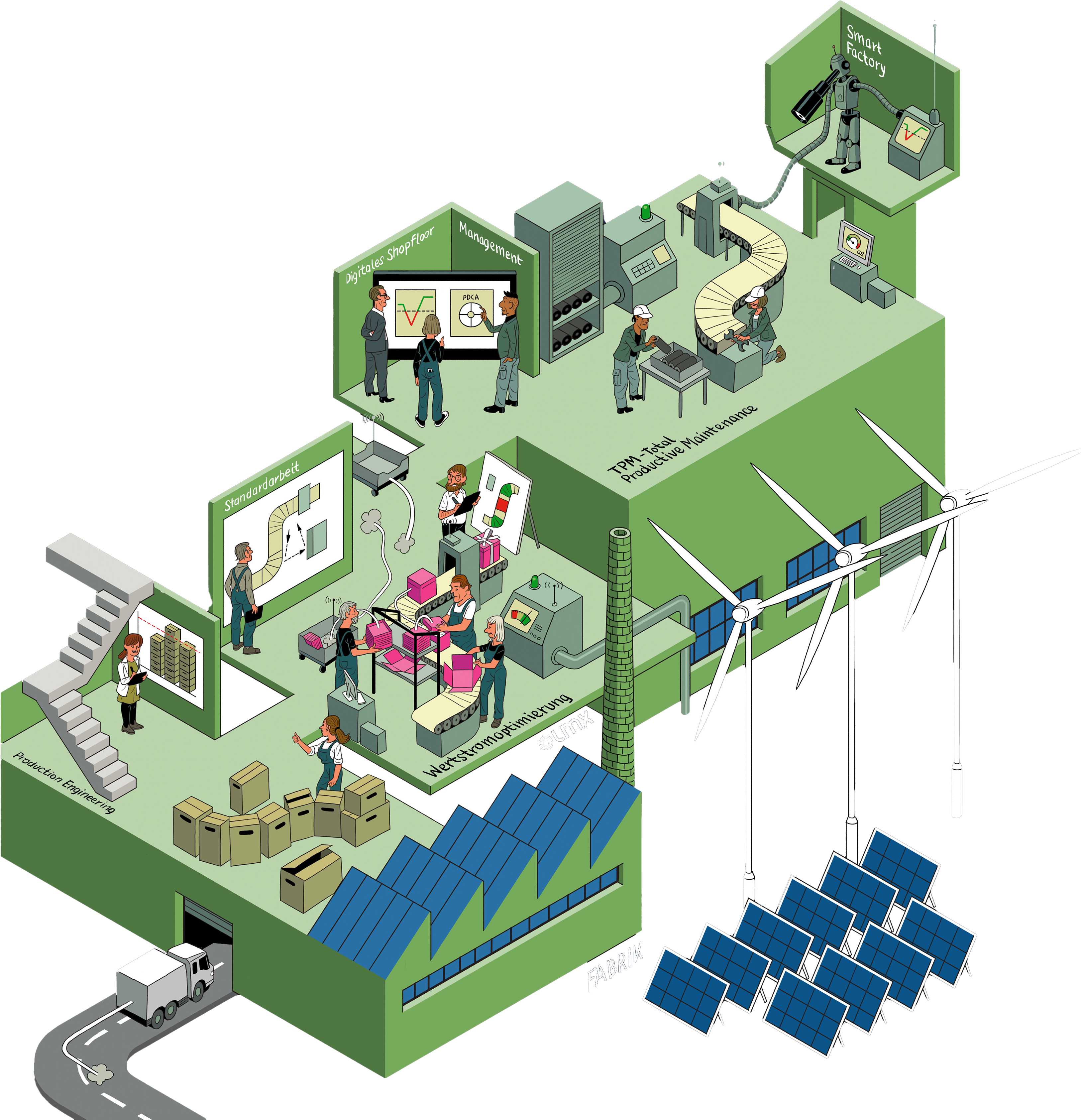

The target of lean maintenance organizations is to provide optimum support for plant availability while keeping costs to a minimum.

Lean Maintenance

An appropriate design of maintenance processes is possible if the maintenance requirements for the individual plants are evaluated based on the value stream. This ensures, for example, that a bottleneck plant is maintained at a higher cost than machines of lesser importance for the functioning value stream.

For tasks in the area of lean maintenance, experts with proven special knowledge are available as contact persons in the LMX team.

Typical results

- Increase in productivity

- Reduction of lead time

- Reduction of maintenance costs

- Increase in plant availability

- Increase in plannable maintenance activities

- Reduction of "firefighting actions

- Synchronization of maintenance with the production system

Ralf Langmaack

Partner

Phone: +49 211 63 55 89 60

Fax: +49 211 63 55 89 69

Email: info@lmx.eu

Lean Management & Digitization 2025 at Ruhr-University Bochum

Our solutions

Holistic approach to maintenance for the care and repair of equipment in production. It is important here that employees are involved in improvement activities.

Target: Increasing the OEE of plants (Overall Equipment Effectiveness). Overall equipment effectiveness is a measure of the value added by a plant.

Intelligent maintenance takes into account digitization, monitoring and automated evaluation of production plants and buildings as well as the technical infrastructure of companies.

Target:Higher plant availability, lower maintenance costs, location-independent maintenancem Real-time data